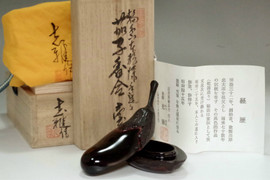

Japanese Lacquer Natsume with Autumn Grasses Design by Shinde Kōhō, Wajima ware #5316

- SKU:

- 5316

- Shipping:

- Calculated at Checkout

width: approx. 6.7cm (2.64in)

height: approx. 7cm (2.76in)

weight: 55g (w/ box 144g)

This exquisite natsume (tea caddy) is a modern lacquerware piece created by Shinde Kōhō, a renowned craftsman of Wajima-nuri lacquerware. The lustrous black lacquer surface is beautifully adorned with gold maki-e designs of autumn grasses, including bamboo and bush clover, meticulously rendered in a realistic yet stylized manner. The continuous pattern flowing across the lid and body enhances the vessel’s visual harmony, while the elegant shine and subtle relief of the gold design evoke a refined sense of seasonal transition. The robust foundation and polished finish characteristic of Wajima lacquer ensure both durability and grace, making this a highly functional and aesthetically accomplished tea utensil. The artist’s signature is neatly inscribed on the base, and the original paulownia wood storage box (tomobako) is included, attesting to the piece’s authenticity and excellent preservation. This work exemplifies the pinnacle of contemporary Japanese lacquer artistry and is a refined addition to any tea ceremony or collection.

**Wajima Lacquerware (Wajima-nuri)**

Wajima-nuri is lacquerware made in Wajima City, Ishikawa Prefecture. The characteristic feature of Wajima-nuri lies in the use of Wajima ground powder, which is unique to the area. The ground powder from Wajima is made of high-quality clay and is used as a base material, enhancing the durability of the lacquerware. Moreover, the aesthetic appeal of Wajima-nuri is a significant aspect of its charm. The lacquerware is known for its carved decorations filled with gold, and the use of gold and silver powders in a technique called "Maki-e" is particularly renowned. The elegance achieved using gold and silver is visually striking. Wajima-nuri lacquerware, which undergoes more than a hundred steps before completion, is not only durable but also repairable if damaged.

**History**

The origins of Wajima-nuri are unclear, with theories suggesting it was introduced during the Muromachi period by monks from Negoroji Temple, and others stating it was spread by monks fleeing the conflicts of the Sengoku period. Commonly, it is believed to have evolved from daily-use Negoro lacquerware. By the early Edo period around 1630, it had transformed into the form closer to modern Wajima-nuri, with the process largely stabilizing between 1716 and 1736. Before its designation as a national traditional craft in 1975, Wajima-nuri was primarily used for practical items at ceremonial events. Today, it also carries an artistic value.

**Production Process**

1. **Wood Base**

Creating the wood base involves preparing the prototype of items like bowls before lacquer application. Keyaki (Zelkova) and Mizume (Birch) are primarily used, with the wood left to naturally dry for 2-3 years after cutting. After thorough drying, the wood is roughly shaped. Wajima-nuri does not proceed to fine carving immediately; instead, it undergoes a smoke drying process using sawdust, followed by months of natural drying before final shaping.

2. **Undercoat**

The undercoat process unique to Wajima-nuri involves using special ground powders. First, slight carvings are made to prevent damage from cracks, which are then covered with an undercoat for reinforcement. "Kisemono-zuri" involves reinforcing vulnerable areas with cloth. The undercoat is meticulously applied, focusing on areas prone to damage, creating a robust foundation. The entire piece is then coated with a mixture of raw lacquer and polishing powder.

3. **Top Coat**

The top coat is applied evenly over the undercoat. The lacquer used is processed alongside earlier steps, beginning with collecting it from trees between June and October. Only about 200g of lacquer can be collected from a single tree per day. After collection, the lacquer is filtered and purified. Wajima-nuri uses refined lacquer, which is treated to prevent fading, ensuring longevity. The top coat is applied in a dust-free environment at optimal temperature and humidity.

4. **Decoration**

After the top coat, the lacquerware is polished to a shine in a process called "Roiro". Delicate sanding materials are used to avoid scratches. Decorations such as Maki-e and inlaid gold or silver are then applied, enhancing the beauty of Wajima-nuri lacquerware.