Loading... Please wait...

Loading... Please wait...Currency Displayed in

- Home

- SOLD ITEMS

- Mori Togaku (1937- ) Bizen pottery sake cup #4503

Categories

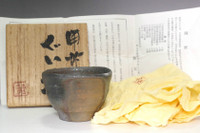

Mori Togaku (1937- ) Bizen pottery sake cup #4503 for sale

Product Description

Up for sale is this "Mori Togaku (1937- ) Bizen pottery sake cup #4503" If you have any questions please contact us before buy it. No reserve.

- width: approx. 5.3cm (2 3⁄32in)

- height: approx. 4.6cm (1 13⁄16in)

- weight: 65g

Mori Togaku (1937- )

His real name is Saizo. He is the eldest son of Mori Hidetsugu, a member of the family of six Bizen kiln owners. In 1963, his work was selected for the first time for the Japan Traditional Crafts Exhibition, and since then it has been purchased by the Museum of Modern Art, Kyoto. He was awarded the President’s Prize at the East Chugoku Branch Exhibition. He is a regular member of Japan Kogei Association.In 1977, he built the Aioi-oh-gama Kiln (46 meters long climing kiln), and in 1981, he built the Kanpuzan-oh-gama Kiln (53-meter-long climbing kiln) at the Sabukaze Pottery Village in Ushimado, Okayama Prefecture.

Bizen ware

Bizen ware is Japan's oldest pottery-making technique, introduced during the Heian period (794-1192). It is a type of pottery identifiable by its iron-like hardness, reddish brown color, absence of glaze, and markings resulting from its wood-burning kiln firing. The surface of Bizen ware is entirely dependent on yohen (discoloration of the ceramic by the kiln). Characteristic features include Hidasuki, a red and brown fire-cord decoration created by rice straw wrapped around pieces, and Enokihada, a hackberry glaze spotting produces by pine ash.

Bizen Ware Clay

I sometimes go to ceramics manufacturers to learn about ceramics. While most pottery you see is used for tea, a lot of Bizen ware is used for sake and boiled food. While this is occasionally difficult for somebody like myself who does not drink, it speaks of how Bizen ware goes well with Japanese alcohol and cooking.

The material used to make Bizen ware comes from a layer of clay called "hiyose" found in the vicinity of Imbe. It can only be collected in a few specific areas, and back in the Momoyama period most of the clay was collected from rice fields.

Dirt in rice fields is insulated from the air, and it is a breeding ground for organic matter, turning it into a viscous clay.

Rice fields are kept topped off with water from the spring planting until the fall harvest, and the dirt in these fields undergoes a continual, natural separation process, resulting in a viscous clay. In addition, when the fields are harvested the water is drained, and the sun shines upon the ground. This causes the water preferring microbes and water adverse microbes to reciprocally multiply, leading to the formation of good soil, which becomes exceptionally viscous clay that is good for pottery.

Due to this process, a single spoonful of the clay contains over one hundred million microbes, and putting the clay in storage to rest allows 80 varieties of yeast to grow.

A majority of these are antibiotics known as penicillin, and longtime Bizen ware potters often say, "If you get injured rub some clay on it."

Hiyose is very viscous and has a low resistance to fire, and compared to other types of pottery clay it contains a lot of iron. Because Bizen ware does not use glaze, potters are extremely sensitive to the composition of the clay. Ensuring a high quality clay is of top importance to the artist.

A piece of Bizen ware created from carefully processed clay, even if it does not appear spectacular when first purchased, after years of continued use will transform into a fine piece that hardly resembles the original.

Bizen Ware Background

1 "Sangiri"

sangiri.jpg kumadori2.jpg

Sangiri and Kumadori (kabuki shading)

During firing, a portion of the piece is buried in ash or soot, and due to reduction firing via restricted airflow, the portions that the flame touches turn reddish brown, while the portions covered in ash turn black or gray.

The line between these regions looks almost like a frame and is called "kumadori" (shading), and in the finest pieces there are whites layered on top of yellows, with more yellows layered on top of that.

Because they are fired in the part of the kiln closest to the flame, damage and deformations are common, and only a very small quantity can be fired at a single time.

Originally the inside of the furnace was partitioned by a san (crosspiece), and the pattern arose below the san, leading to the term sangiri.

There is also the separate method of "sumisangiri," said to be discovered by Kaneshige Toyo. With this method sumi (charcoal) is added later to artificially give the appearance of sangiri to pieces that did not change much during firing, and this method is commonly used today. However, when compared to natural sangiri these pieces give off a different feeling, and the two methods are distinct from one another.

2 "Haikaburi" (ash covered)

haikaburi-2.jpg

During firing pieces are buried in wood ash or soot, which dissolves and chars from the process. This is another reason why, with the firing done in the part of the kiln closest to the flame, damage and deformations are common, and only a very small quantity can be fired at a single time.

3 "Goma"

goma.jpg tamadare1.jpg

The wood ash falls naturally, and due to the high temperatures as it melts it gives the appearance of a glaze. It looks as though goma (sesame seeds) have been sprinkled on the piece, so this is called goma. There are various colors, including whites, yellows, and greens. As the goma melts, it becomes a substance that looks like a flowing glassy glaze, which is called "tamadare" (egg dripping).

4 "Kasegoma"

kasegoma-2.jpg

One variety of goma comes when ash that has been stripped of its moisture from the heat clings to the piece, and as it melts it gives the appearance of ash color, rough and dry skin. The feeling of wabi (aesthetic emphasizing simplicity) given off by such pieces has been particularly prized in tea ceremonies since ancient times.

5 "Hidasuki"

hidasuki.jpg

Kaneshige Toyo's younger brother Sozan created this form of firing, and he himself said, "My older brother (Toyo) left this for me."

Firing is done without direct contact from the flame, and the parts that are wrapped in straw have a reaction with the iron in the clay and the alkali in the straw, causing a red coloring. On the white background the vivid red left behind by the straw looks like a sash, so it is called "hidasuki" (red sash).

6 "Botamochi"

botamochi.jpg

Originally, because space in the kiln was limited, pieces were piled up when fired. The spaces where they touched were discolored, and those parts did not match the style of the rest of the piece. Nowadays, highly fire resistant cracker shaped discs called "bota" are often placed on pieces when firing to intentionally create botamochi patterns.

7 "Aobizen"

aobizen.jpg

Bizen ware is normally fired using an oxidized flame, but sometimes due to the conditions of the pieces in the kiln or other factors there is reduction, and this can cause the entire piece to have a blue tint. This is called aobizen (blue Bizen), and among the many types of variations it is among the rarest and quite highly valued.

There is also a separate method where salt is added, which causes alkali to coil around the surface, and via reductive cooling this can also give a blue tint. This method is distinct from aobizen, and it is called "shioao" (salt blue) or "shokuenao" (table salt blue).

8 "Kurobizen" (black Bizen)

kurobizen-1.jpg

Coating a shaped piece with clay that causes black coloration or using clay that will become black when fired is called "imbede" (Imbe method). This coating technique can often be seen in pieces of ancient Bizen ware dating back to the Edo period.

9 "Ishihaze" (stone popping)

ishihaze.jpg

During drying or firing the shrinking of the clay can cause stones on the inside to rise to the surface, and this is also called ishikami. Sometimes this can cause a leak in a piece. This gives the appearance of the stone popping out of the piece, and it is very highly valued as it presents a good scene.

The charm of Bizen ware

1. It doesn't break even when thrown

Bizen ware is fired without glazing at a temperature of over 1200 degrees for approximately two weeks, giving it a higher level of strength than other pottery. That is why, along with Arita ware, it has long been known as pottery which "Doesn't break even when thrown...."

2. Cold beer, warm tea

As Bizen ware has an elaborate internal structure, it has a high specific heat capacity. Because of this, it has strong heat-retention properties, and is difficult to heat and to cool.

3. Delicious beer with delicate foam

As Bizen ware has minute irregularities and high foaming abilities, and the foam is delicate and long-lasting, it retains the flavor, allowing it to be enjoyed even more.

4. If you leave it for a long time, it improves the flavor of sake

Bizen ware contains minute interior pores, which cause a certain extent of subtle permeability. Due to this, the aroma of sake, whiskey, and wine increases and mellows, promoting a rich flavor transformation.

5. It delivers delicious dishes

Bizen ware has more small irregularities on the surface compared with other pottery, so food doesn't stick to the dishes and is easy to remove, and it has weak moisture evaporation properties, which prevents food drying out.

6. Fowers in vases last longer

Bizen ware has minute pores and a certain extent of permeability, so it maintains the condition of fresh water for a long time, making flowers last longer.

7. It takes on a smooth texture with use

By breaking Bizen ware in, the edges of the fine irregularities on the surface are gradually removed, and its quiet charm increases the more it is used.

shop policy

AppraisalWe are a very small team with limited resources and are unable to conduct scientific age verification or appraisals by the artist’s descendants. We evaluate items using specialized reference books, scholarly resources, and knowledge inherited from senior experts in the field. If a purchased item does not meet your expectations, please feel free to contact us. We sincerely value your opinion.

Cancellation and Return

We accept return only if you contact us within 30 days after you receive the items. Return-shipping costs are the buyer’s responsibility. If you ask a cancellation before shipping the package, we may ask a 20% restocking fee.

Shipping

+ Shipping to the USA, Europe, and Asia is free. For other areas, please contact us. Shipping is via EMS or DHL.

+ VAT is not included in the item price.

+ We will ship within 3 business days. Shipping time is usually around a week.

Insurance

We are not responsible for delays, returns, damage or loss due to customs or postal processing. EMS is insured (the amount on the label is the guaranteed amount). If you choose DHL, we recommend that you purchase additional insurance. Please note that if you choose the DHL drop service option, insurance will not be applied.

Taxes

Import duties, taxes and fees are not included in the item price. If your country requires customs duties, etc., it is your responsibility to pay them.

To customers buying tableware

Our products are mostly used. We sell them in the same condition they were purchased, please be sure to clean them thoroughly before actually using them.